A Guide to Lifting Mature Wire Rootball (WRB) Trees

This is a general guide to lifting your mature rootball tree off the delivery truck.

Most times the driver will be in a flatbed truck or curtain sided truck and will not assist in the unloading of your trees. It is your responsibility to make sure you have the knowledge and resources available to unload safely, and in the time allotted by the delivery company.

To do this, you will need to know how much each tree weighs. The chart below is an average as each species can weigh more or less than this e.g. hardwoods, wet and clay soils can easily be 30% heavier.

A forklift is the easiest way but many landscapers only have the likes of a mini-digger available meaning you will have to use lifting slings and possibly shackles. The table below shows you an approximate weight to expect with each tree girth size.

WRB (Wire Rootball Tree) Approximate Weight Chart

| Tree girth (cm) |

Whole Tree (kg) |

|---|---|

| 6-8 | 30 |

| 8-10 | 50 |

| 10-12 | 70 |

| 12-14 | 80 |

| 14-16 | 100 |

| 16-18 | 150 |

| 18-20 | 200 |

| 20-25 | 250 |

| 25-30 | 350 |

| 30-35 | 500 |

| 35-40 | 650 |

| 40-45 | 850 |

| 45-50 | 1,100 |

| 50-60 | 1,600 |

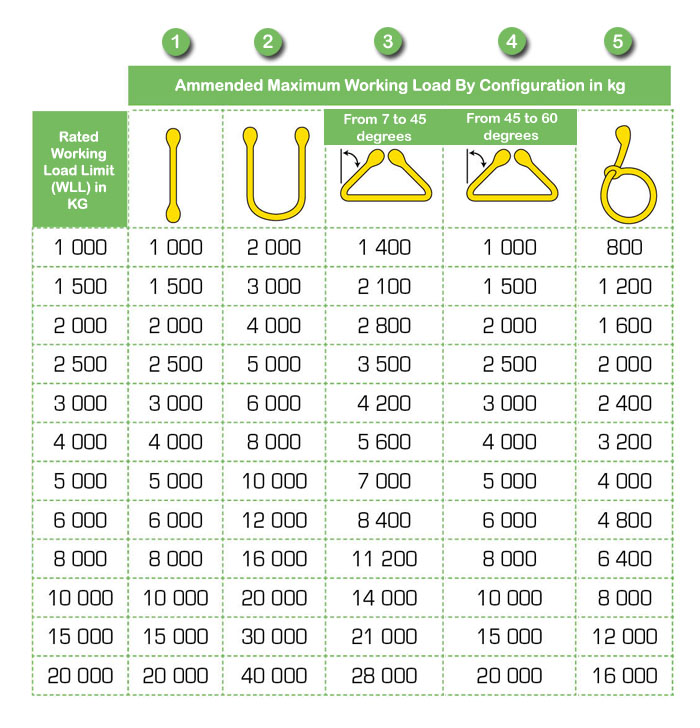

Working Load Limits (WLL)

It might sound odd, but the WLL rating you get with slings e.g. 1 T (1 tonne or 1000 kg) is not the maximum it can carry as you will see from the chart below. How you configure your sling determines the safe working load. A 1 T sling could actually carry up to a 2 T load, see loading configuration 2.

When using the two sling method to remove your tree, you will likely be using method 3 or 4 and as you can see, there is a difference even though they look very similar. Method 2 will only apply if you are using a spreader bar giving you effectively 2 lifting points that keep the sling vertical.

Most slings will fail at around 7 times more than they are rated for but it is still a bad idea to go over their safe working load as continued overloading will shorten the life of your sling.

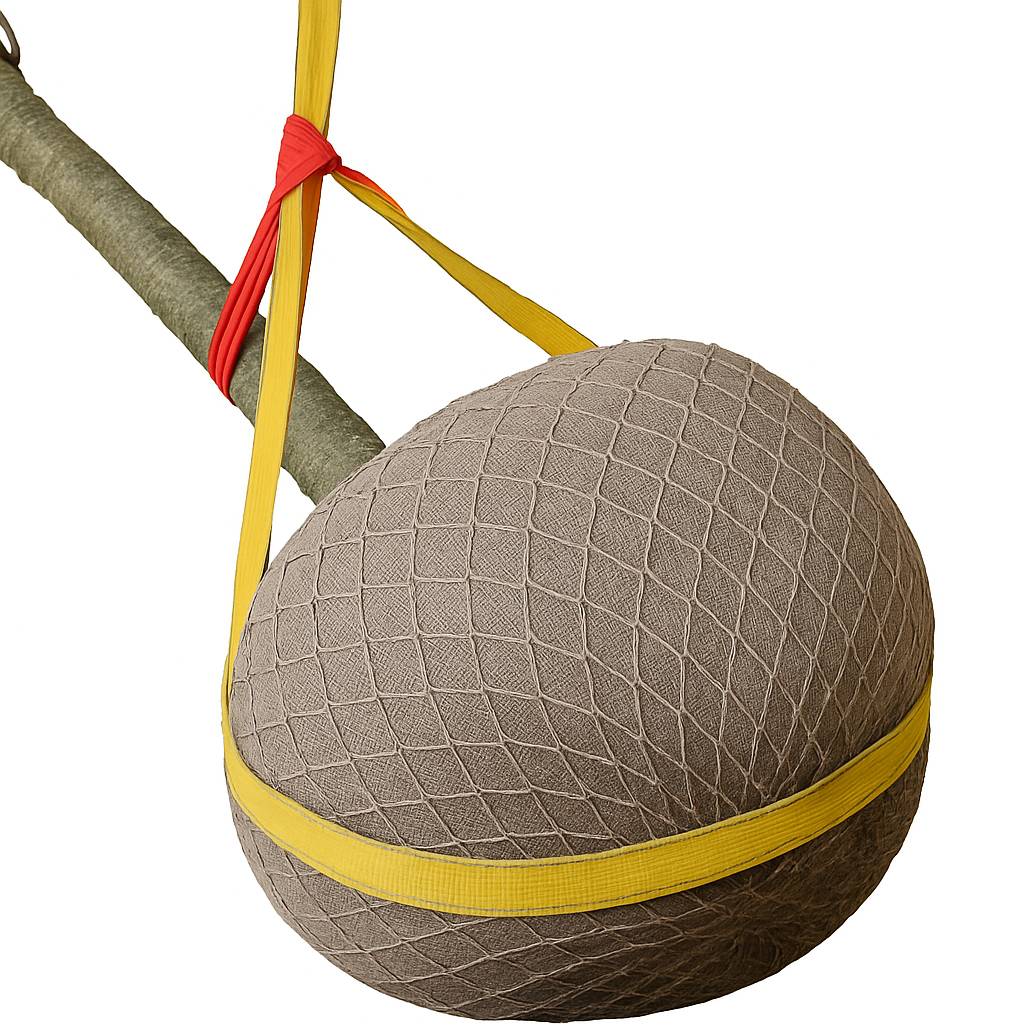

Industry standard lifting method – two sling method

At all times, protect the bark of the tree.

The two sling method means all weight is carried by the yellow sling under the root ball and the red one is there for you to help guide and steady. No load should go through the red sling.

Do not wrap a sling around the bark so that it creates a choke i.e. something that tightens when lifted. The wider the sling, the better.

To get this configuration feed each yellow loop end through each loop of the red sling and then attach both yellow lifting loops to your lifting point. You may need to raise and lower the load several times to get the balance right.

Don’t use endless loops

An endless-loop sling, also called a round sling, is a continuous circular tube of polyester with no ends or eyes. Although strong, it is designed to choke or wrap around loads, not to sit flat under a heavy object. A webbing sling, by contrast, is a flat strap with reinforced lifting eyes at each end, allowing it to lie wide and stable beneath the rootball.

Endless loops tend to roll, bunch up and bite into the soil or wire basket, which makes the lift less steady and increases the risk of damaging the ball or losing balance during unloading. Webbing slings spread the load, stay flat, are easier to place, and provide a more predictable lift, making them the safer and more suitable choice for unloading WRB trees.

Rookie Mistooks

- Not checking the equipment lifting charts. What you can lift at maximum extension is very different to what you can lift closest to the cab.

- Inexperienced driver creating swing on the load. Rotate/slew slowly to prevent it. If swing is created, stop moving and wait for it to stop OR once stopped wait until it swings past the imaginary vertical line underneath the lifting point and then move the boom in the same direction it is swinging.

- Using round slings instead of flat webbing ones. Width is your friend for this job.

- Thinking bark is tough stuff. It might be, the cambium underneath it is not.

- The ground you are on looks strong enough. Assume it is not until you have tested it is.

- Assuming the driver is paid to make your life easier and of course he wants to help.

- Not paying attention to the sling configuration chart.

- We can just drag it off. The smaller feeding hairs could be damaged and establishment is delayed.

- The canopy acting as a sail and rotating. Expect that it will.

- Not checking your slings. Look for cuts and abrasions.

- Not keeping the load low. If you don’t have to raise it then don’t.

- Standing under the load, inside the swing arc or between the load and a fixed object. That is something for you to be crushed by.

- Not having a plan that everyone knows and understands. At a minimum agree one word to stop the whole process so the gaffer can assess.

Recommended equipment

Recommended

- Telehandler

- Hiab / lorry-mounted crane

- Mobile crane

- Excavator (with lifting point)

- Wheel loader

- Rough-terrain forklift

Use with a lot of caution

- Forklift (standard warehouse type)

- Moffett forklift

- Tractor loader / front-end loader

- Skid steer with lifting attachment

- Backhoe loader (JCB 3CX)

- Workshop jib crane

- Overhead gantry crane (yard)

- Mini digger using bucket as hook point

- Pallet stacker (manual or powered)

- Hand winch / chain block from beam

Desperate / avoid

- Vehicle towbar + rope pull

- Ratchet strap winched to a fixed post

- Pickup truck bed used as drop platform

- Two wheelbarrows as support points

- Truck’s own pump truck to “nudge” load

- Builders using scaffold tubes as rollers

- Pivoting rootball on tyres

- Push from behind with sack truck as lever

- Rolling on small logs / scaffold poles

- Manual drag on sheet / tarp

- Four-person manual drag

Never recommended

- Improvised lever bars under rootball

- Pushing / shoving rootball directly

- Dropping or sliding off truck bed